Gear

Gear is a cylindrical teeth arrangement that transmit rotating power from

driving shaft to driven shaft. There are varsity's types of gear. Typically,it

is used to change the speed and torque of driving and driven shaft.Gears are using in many industrial applications to transmit power and motion to different types of mechanical device like Automobiles and machines.

If two gear mesh is connected together and start turning any directions the second gear will turn in opposite directions. When a small gear is connected to a driving shaft and another larger gear is attached with driven shaft the speed will decrease of driven shaft per unit of driving shaft rotation.

There are variety's of gear provides different efficiency and advantages.

Specially gear is used for

1. Rotational direction change

2. Rotational speed control.

3. Increasing power

4. Synchronized the rotation of two axis

Types of gear

Gears are classified by the design or construction of the teeth.1. Spur gear

2. Helical gear- Single helical gear and double helical gear

3.Herringbone gear

4. Rack and pinion gear

5. Worm gear

6. Bevel gear

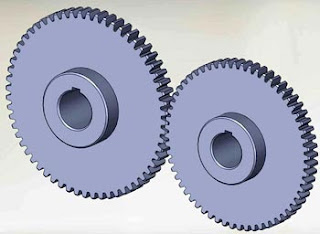

Spur gear

Usually Spur gears are used to transmit power between two parallel connected shafts. When a several amount of parallel and straight teeth cut around the cylindrical shaft is called spur gear. Spur gear generate radial force and transmission efficiency is very high. There are two types of spur gear one of them is External spur gear and other one is internal spur gear. When gear teeth attached outer surface of a cylinder is an external gear and if the gear teeth attached to inner side of cylinder surface is an internal spur gear.

Helical gear

Helical gear teeth are not parallel and it is cut with an angle to the axis that means helicoid teeth around the cylindrical shape gear. Helical gear produce low noise and can transmit higher loads. During the transmitting of loads they generates thrust loads around the axial directions. Helical gear operates in quieter and smoother than spur gears.

Herringbone Gear

When two helical gears is joined together in opposite directions and transmit force to parallel or non-parallel shaft is called Herringbone gear.They does not produce much more loads than helical gear but it can handle smooth power transmission.

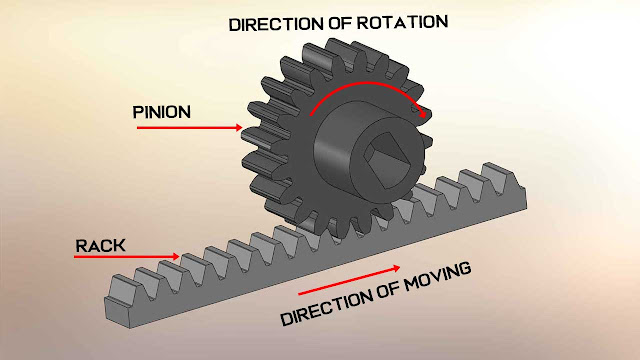

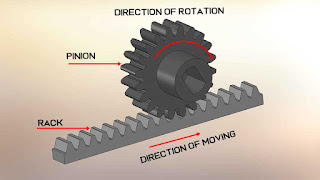

Rack and pinion gear

Rack and pinion gear transmit rotational motion to linear motion. When pinion start turning the rack gain linear motion. A pinion that consist a couple of teeth in a cylindrical body and a rack that has several number of teeth on the linear rectangular shaped body and they are connected with meshes teeth. Rack and pinion gears are the most widely used in Automobiles and machine tools.

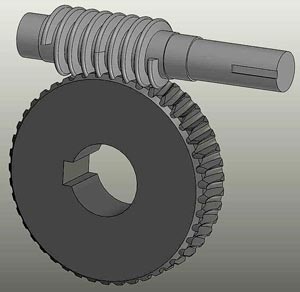

Worm gear

A cylindrical gear that is meshed with worm and transmit the power between non-parallel and non-intersecting shafts. It's gear ration is very large and can handle quiet and smooth operation. Here the cylindrical gear can't turn the worm where only worm can turns the cylindrical gear thus this type of gear arrangement offers self locking system. The main disadvantages of this gear is low transmission efficiency and generates friction and require continuous lubrication.

Bevel gear

The gear which have a Spiral or helical teeth those are cut along the cone and transmit force between two intersecting or perpendicular shafts. Bevel gear can't transmit more torque and require right angle gear drive. Spur gears are the most widely used in printing presses automobiles and marine applications.

Our facebook group

Post a Comment