Hydraulic directional control valve

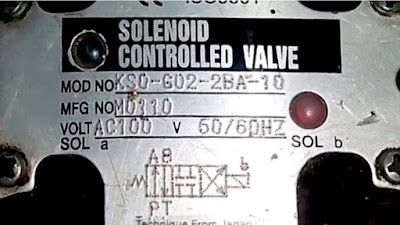

Usually Hydraulic directional control valve is using to the hydraulic system to control the the fluid flow, changing the direction of flow and cut off the flow. Every directional valve construction is different depending the uses of their application and the nameplate diagram on the top of the valve indicates the type of their construction and applications of its uses.Four types of valve most commonly used to maximum hydraulic system

- Close center valve

- Open center valve

- Float center valve

- Tandem center value

1. Close center Hydraulic directional control valve

Usually this types of valve Uses where hydraulic cylinder needs to stop multiple position when up and down manually and automatically. When the valve stay center position then relief valve is being active and the flow of fluid go to the tank.

Advantages:

- You can stop your actuator in multiple position.

Disadvantages:

- Hydraulic System noise is high

- Vibrate the hydraulic System

- More Power losses

2. Open center Hydraulic directional control valve

The hydraulic system that's no need to stop hydraulic cylinder in any position and need to up down the cylinder very fast there using this types of valve. When the valve is in center position then the flow of fluid go to the tank without any interruption.

Advantages:

- Pump keeps in unloading condition

- Produce less overheat for the system.

- Less system vibration

Hydraulic directional control valve

Disadvantages:

- Not possible to stop cylinder in multiple position.

3. Float center Hydraulic directional control valve

This valves are likes open center valve. If the spool stay in center position resulting the pressure port are closed thus relief valve works to unload the excessive pressure.Top stop cylinder in multiple position it is used pilot operated checked valve.

Advantages

Float center Hydraulic directional control valve usually used in the system depending its design. There has no additional advantages.Disadvantages:

- Not possible to stop hydraulic cylinder in multiple position.To stop cylinder in multiple position need pilot operated check valve.

- When spool stay in center position then pump is keeps in loaded.

- Creates excessive noise and vibration for the system.

4. Tandem center hydraulic directional control valve

This types of valve is same as the close center valve. If needed the hydraulic cylinder for clamping in different position there using this types of valve. If the valve spool stay in center position fluids oil will go to the tank without any interruption.

Advantages:

- Can stop hydraulic cylinder in multiple position.

- Pump keeps in unloading condition

- Less overheat creates to the system

- Less vibration

Disadvantages:

- Usually these types of valves has no disadvantages.

Hydraulic directional control valve

Basic hydraulic system components. Basic pneumatic system. Basic hydraulic components pneumatic system

Post a Comment