What is Reciprocating Compressor?

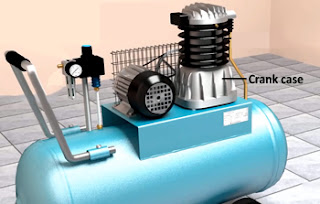

Reciprocating compressor is also known as Piston compressor. It is a positive-displacement device that compresses gas through a piston and pushes the gas at high pressure. It follows reciprocating rules.Components of Reciprocating Compressor

The basic components of the reciprocating compressor are:Cylinder: Cylinders are usually attached to the main body of the compressor. Depending on the size of the compressors these are either separable or not. The separable cylinders are equipped with liners. If a cylinder gets damaged or wasted then without changing the whole cylinder only the liner can be replaced. A cylinder is usually furnished with the cooling system too. Steel and nodular iron are the popular construction materials of a cylinder.

Frame: The other name of the frame is crankcase, it is heavy in weight. Frame holds the moving parts of the compressor and provides support to the crankshaft.

Image source

Crankshaft:It performs a rotary motion and helps the piston to go upwards and downwards. One end of the crankshaft is connected with electric motor by pulley or belt and the other end is connected with the piston with the help of a connecting rod.

Piston:Piston actually controls the reciprocating motion of the cylinder and that is why it is known as the heart of the reciprocating compressor. It helps to compress the gases and push them into the cylinder. To prevent the wasting of gas there remain piston rings between the cylinder and piston. The piston is made of cast iron, bronze, steel, etc.

Bearings:There are different types of bearings and they serve for different purposes. Bearings are fitted all over the frame. Some of them are-

a) Main bearing: Crankshaft is correctly positioned by this type of bearing.

b) Crank pin: These are placed between the crankshaft and the connecting rod.

c) Cross-head pin: These are fitted at the head and the bottom of cross-head.

d) Wrist pin: These bearings provide support by remaining between every connecting rod and cross-head.

Valve: A single end of the compressor has two valves. Suction valves help the gases enter into the cylinder where discharge valves push the gases from the cylinder. The main work of the valve is to direct the gases through the right path. There are three kinds of valves-

a) Ring Type valve: This uses single or multiple narrow connecting rings. This is good to handle liquids. But this valve cannot control the flow constantly with the single valve.

b) Poppet Type valve: The poppet valve is good for medium pressure. This has very high fuel efficiency.

c) Plate Type valve: This is good at controlling high pressures but does not work well for liquids.

Reciprocating compressors are helpful for cleaning machines, normally used in air motors, oil refineries, chemical plants, automobile maintenance stations, and other sectors.

Types of compressor

- Dynamic compressor

- Positive displacement compressor

a) Rotary

- Screw

- Lobe

- Vane

- Scroll

- Liquid ring

b) Reciprocating

- Double acting

- Single acting

- Multistage

- Diaphragm

Post a Comment